2016 ZLG series rectlinear vibrating fluidied drier, SS best steam dryer, powder spiral conveyor

Basic Info

Model No.: ZLG4.5*0.45

Product Description

2016 ZLG series rectlinear vibrating fluidied drier, SS best steam Dryer, powder spiral conveyor

Principle

Raw materials is fed into the machine from the inlet and moves forward continuously along with the level of fluidized-bed under the action of vibration. The hot air passes through fluidized-bed and carries out hot heat exchange with damp raw material. Then the damp air is exhausted out through cyclone separator and duster and the dry raw material is discharged through discharge outlet.

Description

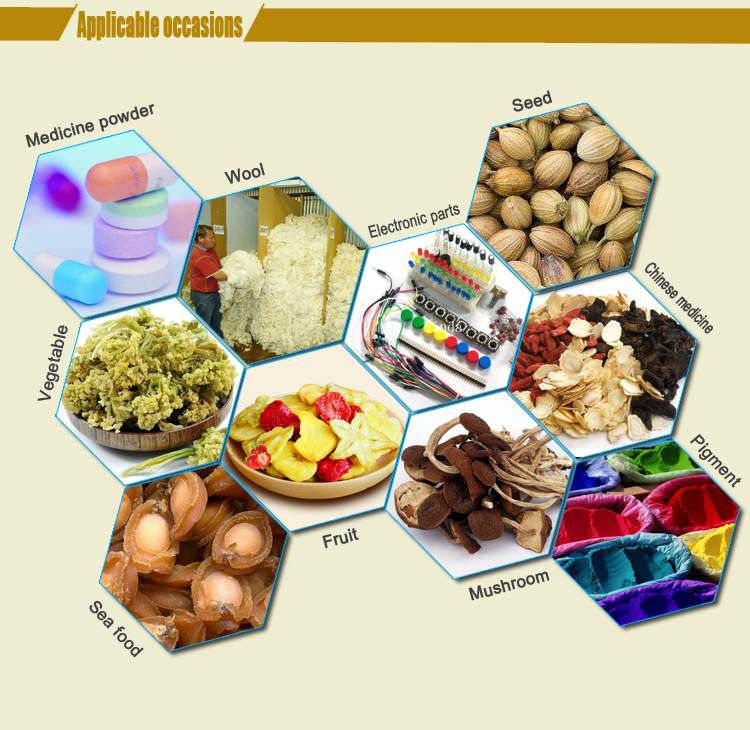

The drier is suitability in chemical industry, pharmaceutical, food ,plastic, oil, slag, salt sugar and so on, for drying, cooling and wetting.

Application

Pharmaceutical and chemical industries: all kinds of press tablet and granule, boric acid, borax, dihydroxybenzene, malic acid, maleic acid and so on.

Foodstuff and construction material industries: less, monosodium glutamate, edible sugar, edible salt, mine residue, bean, seeds and so on.

It can also used for raw materials to add up damp or cooling and so on.

Features

The vibration is created by motor. It is stable in operation and convenient in maintenance, low noise and long life.

High effection, raw material is heated evenly and heat exchange is fully used and dry capacity is high. Compared with ordinary drier, the energy can be saved about 30%.

It is good in regulation and wide in suitability. The thickness of raw material layer and movable speed inside the machine and the amplitude can be adjusted through continuos variable speed.

It is small for damaging the surface of raw material. The equipment can be used for drying raw materials that are easy broken. The drying effect cannot be affected even if raw materials have anomaly shape.

It is sffective to prevent cross pollution between raw material and air because the equipment adapts fully closed structure. The environment of operation is clean.

You can string multi-set to rasied capacity of raw materials, such as polyacrylamide.

Fault Phenomenon | Possible Cause | Elimination Methods |

1, The Temperature Rise Is Not High | 1 Fan Reversal Or Shutdown 2 Steam Flow Or Pressure Is Low 3 Hydrophobic Jam 4 Vent Regulating Improper Or Failure 5 Boxes Or Crack Leakage 6 Electric Heating May Be Short Circuit | 1 To Correct, Repair Or Replacement 2,Eliminate Congestion, To Guarantee The Pressure 3 Repair Or Replacement 4 No Exhaust Or Less Exhaust 5 Stoppage 6 Check The Electrical Heating |

2, The Temperature Is Not Uniform | 1 Left And Right Wind Deflector Improper Adjustment 2 Flat Box Or The Crack Of The Door 3 Material (Workpiece) Volume Is Too Large, Large Block Hot Air | 1 According To The Second Part , 3 Points Do The Debugging |

3, Temperature Lose Control, Too High | 1 Control System Failure (Without Self-Control, The Steam Valve Opening Is Too Big) 2 Vent Improper Adjustment 3 Steam Pressure Is Too High | 1 Check Instrument, Lines, Especially The Steam Solenoid Valve, According To The Electromagnetic Valve Manual Repair Or Replacement. 2 Appropriate Increase The Displacement 3 Appropriate Increase The Displacement |

4, The Drying Time Is Too Long | 1 Temperature Is Not Enough 2 Uneven Temperature 3 Vent Plug 4 Material Laying Too Thick | With Reference To Fault 1 Ruled Out With Reference To Fault 2 Ruled Out 3 Ensure Displacement And Clearfour Minus Expected, Choose The Best Thickness |

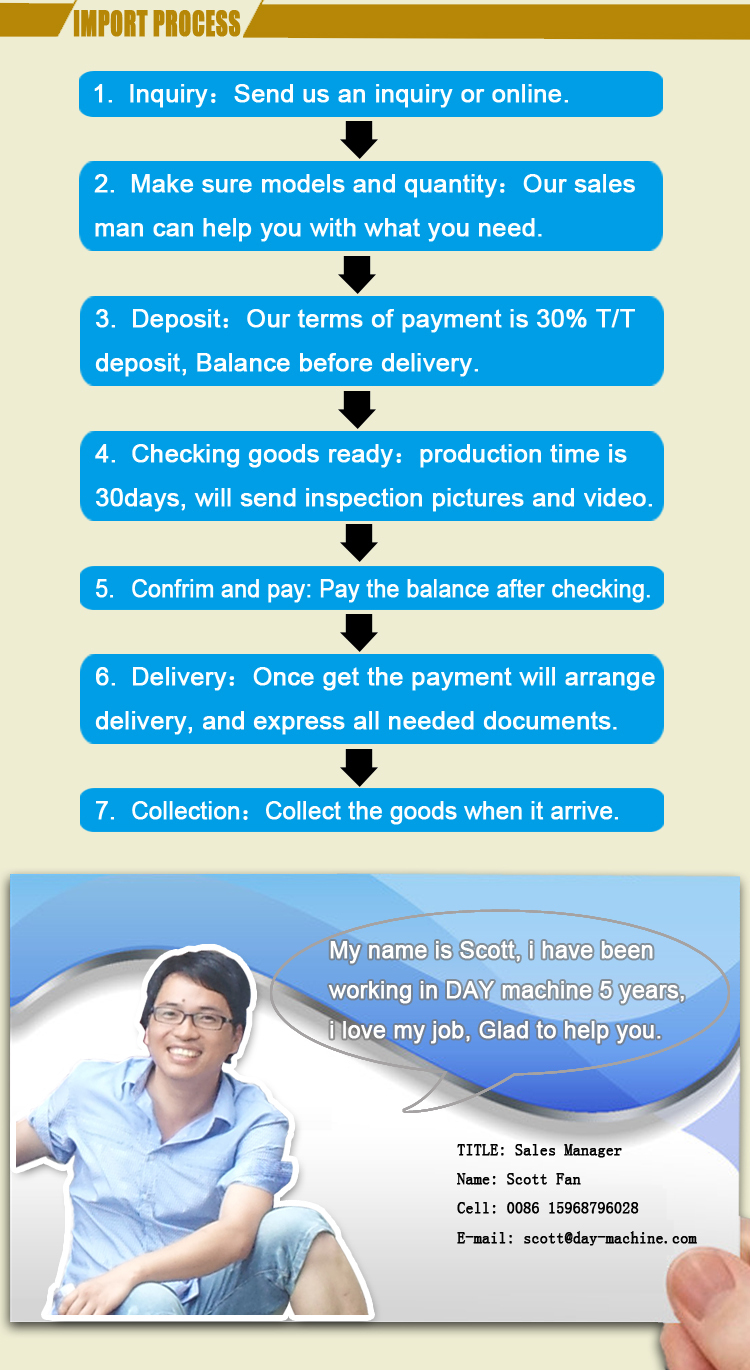

Thanks for your time to read, for 2016 new promotion, we are providing US$200 cash coupon for ZLG series rectlinear vibrating fluidied drier.

Click following picture to get discount code.

2016 ZLG series rectlinear vibrating fluidied drier, SS best steam dryer, powder spiral conveyor

Product Categories : Dryer > Tray Dryer

Premium Related Products